CNC Machining Welding Laser Cutting Aluminium Accessories for Food Equipment / Food Processing Production Line / Fluid Equipment

Basic Info.

| Process | Laser Cutting, Bending, Stamping,Welding |

| Key | CNC Turning Part |

| Name | CNC Parts |

| Tolerance | 0.05mm-0.1mm |

| Color | Customized Color |

| Surface Treatment | Powder Coating, Eletro Plating, Oxide,Anodization |

| Transport Package | Carton |

| Specification | Customized |

| Trademark | Customized |

| Origin | China |

| Production Capacity | 500000PCS/Month |

Product Description

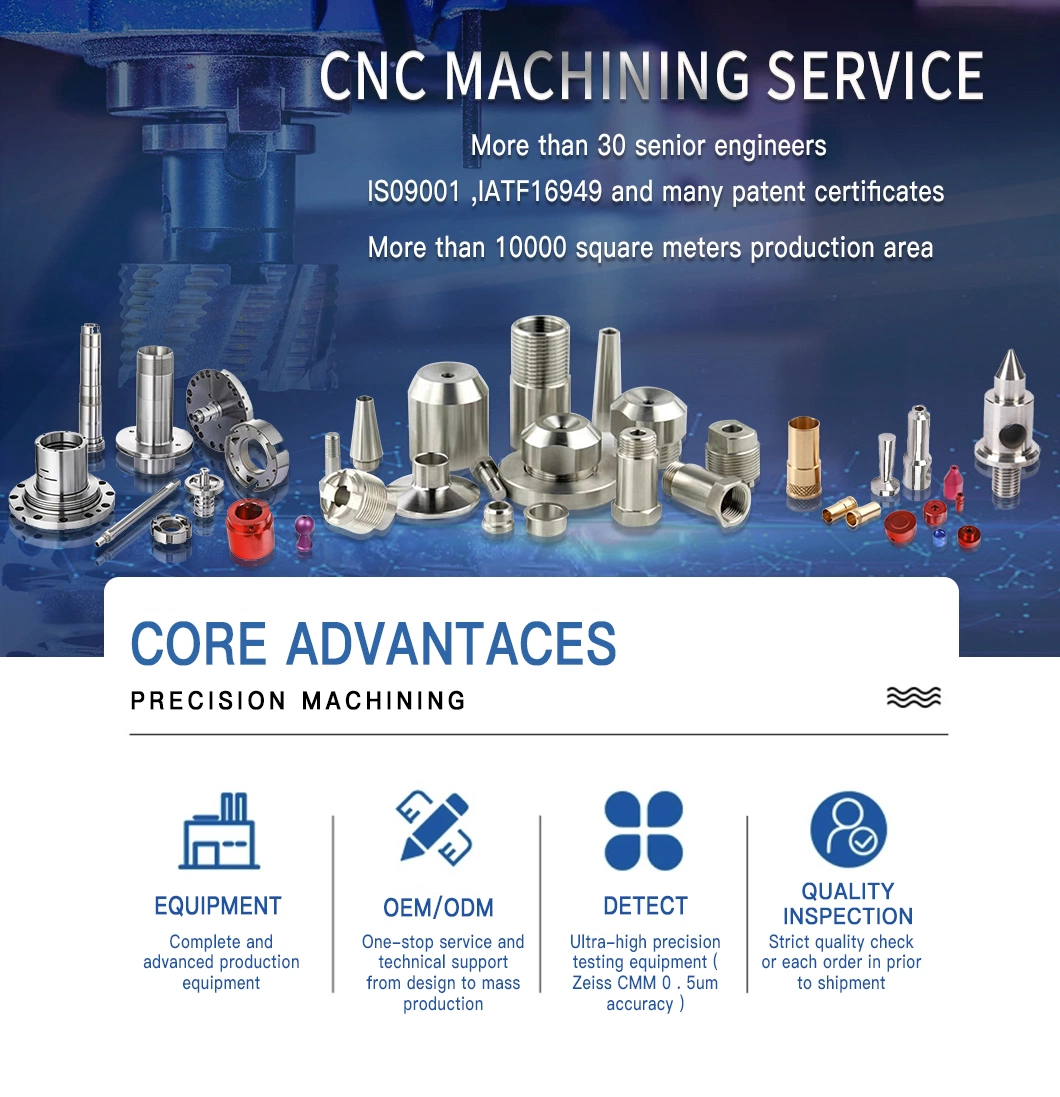

Customized Precision Brass Stainless Steel Aluminum Turning Milling CNC Machining Parts

| Material | 1) Aluminum: AL 6061-T6, 6063, 7075-T etc. |

| 2) Stainless steel: 303,304,316L, 17-4(SUS630) etc. | |

| 3) Steel: 4140, Q235, Q345B,20#,45# etc. | |

| 4) Titanium: TA1,TA2/GR2, TA4/GR5, TC4, TC18 etc. | |

| 5) Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc. | |

| 6) Copper, bronze, Magnesium alloy, Delrin, POM,Acrylic, PC, etc. | |

| Finish | Sandblasting, Anodize color, Blackenning, Zinc/Nickl Plating, Polish. |

| Power coating, Passivation PVD, Titanium Plating, Electrogalvanizing. | |

| Electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench). | |

| Electro Polishing,Chrome Plating, Knurl, Laser etch Logo, etc. | |

| Main Equipment | CNC Machining center(Milling), CNC Lathe, Grinding machine. |

| Cylindrical grinder machine, Drilling machine, Laser Cutting Machine,etc. | |

| Drawing format | STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples. |

| Tolerance | +/-0.01mm ~ +/-0.05mm |

| Surface roughness | Ra 0.1~3.2 |

| Inspection | Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier,CMM. |

| Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge. | |

| Capacity | CNC turning work range: φ0.5mm-φ150mm*300mm. |

| CNC milling work range: 510mm*1020mm*500mm. |

Q1: What information is required for a quotation?A1: You can provide 2D/3D drawings or send your samples to our factory, and then we can make them based on your samples.Q2: Can we sign the NDA?A2: Of course. We will never disclose customer information to anyone else.Q3: Do you provide samples?A3: Yes, we can provide you with samples before bulk ordering.Q4: How do you ensure quality?A4: We have a professional quality control department to ensure quality.Q5: Delivery time?A5: If there is inventory: about 3 days after payment. Mass production: Approximately 20-25 days after receiving the deposit (the exact delivery time depends on the specific project and quantity)Q6: How about transportation?A6: You can choose any transportation method you want, sea freight, air freight, or door-to-door express delivery,